composites

composites

Composites not only play an important role in electrical engineering. In aircraft and vehicle construction, too, the materials with a high proportion of glass or carbon fibers ensure optimum energy efficiency thanks to their exceptional strength and low weight.

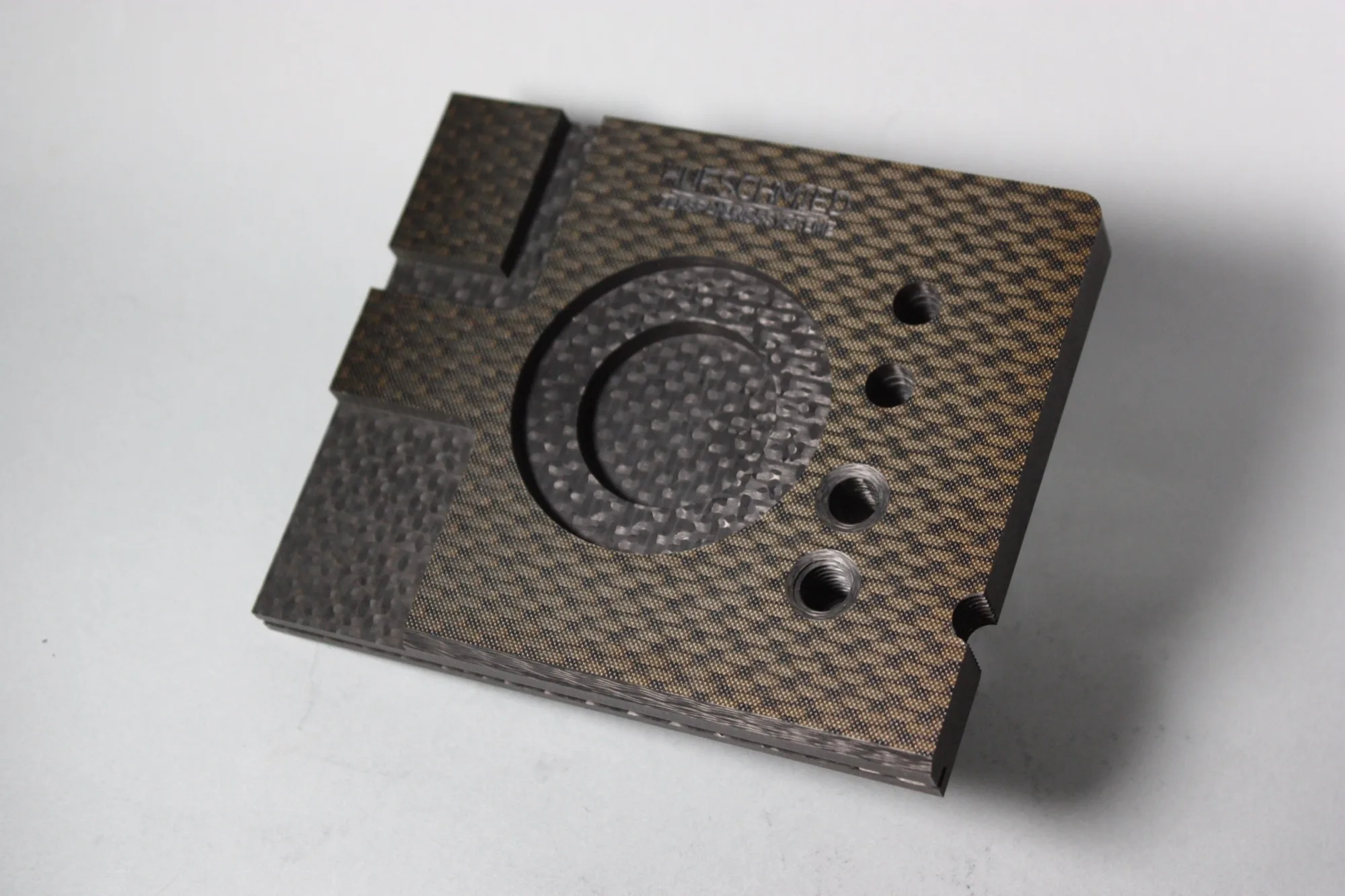

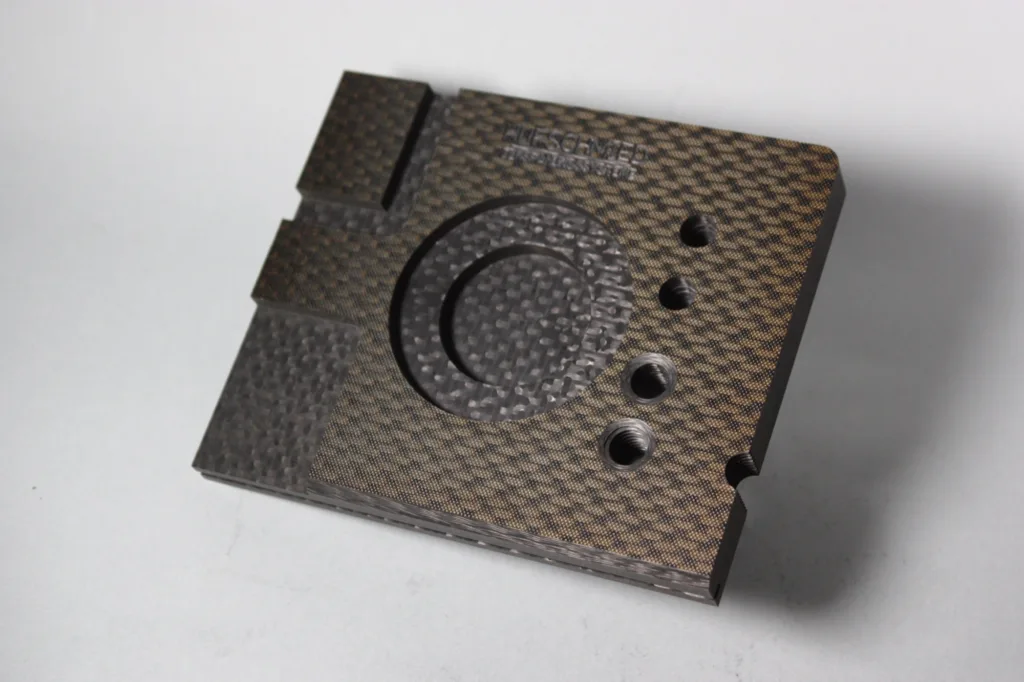

Milling composites for the highest demands

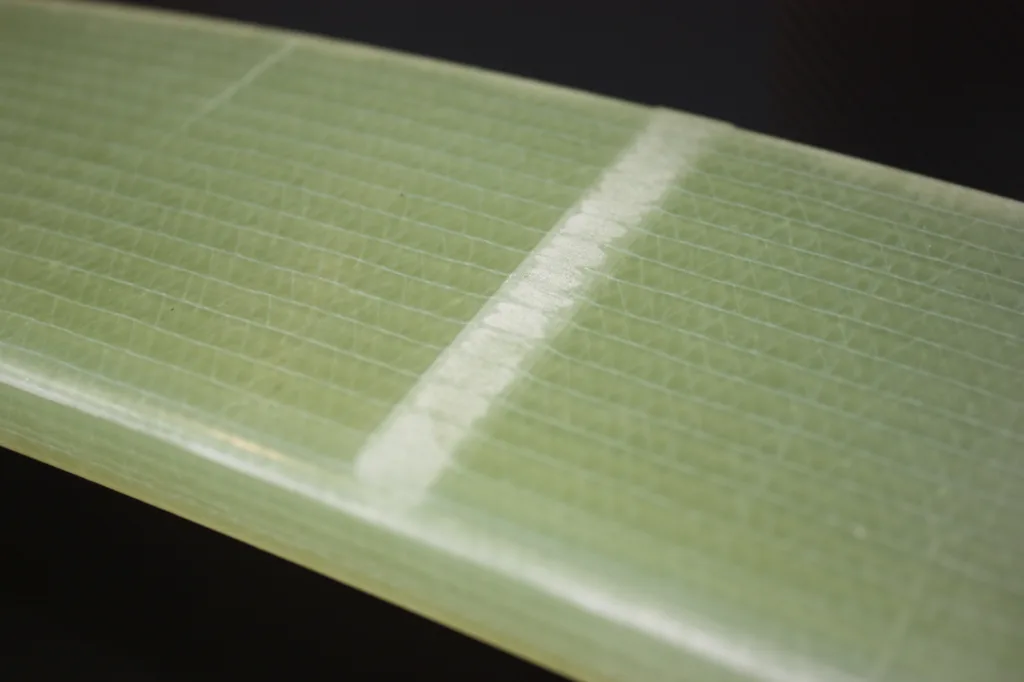

Composites place the highest demands on the process and tool, both in terms of processing quality and tool life. New materials in composites such as ceramic-based fibers and other extremely resistant and inhomogeneous materials require modern, technically sophisticated processing techniques and tools. The components made of composites basically require exact dimensional accuracy and excellent surface quality.

Hufschmied has developed innovative special tools for the processing of fibre-reinforced plastics, which make processing much more reliable and economical. It has Hufschmied has managed through intensive research and development to bring the balancing act between high wear resistance and high cutting edge retention of the processing tool with simultaneous high efficiency in terms of service life and processing speed in its Fiber-Line tools.

Milling tools especially for "cold" machining

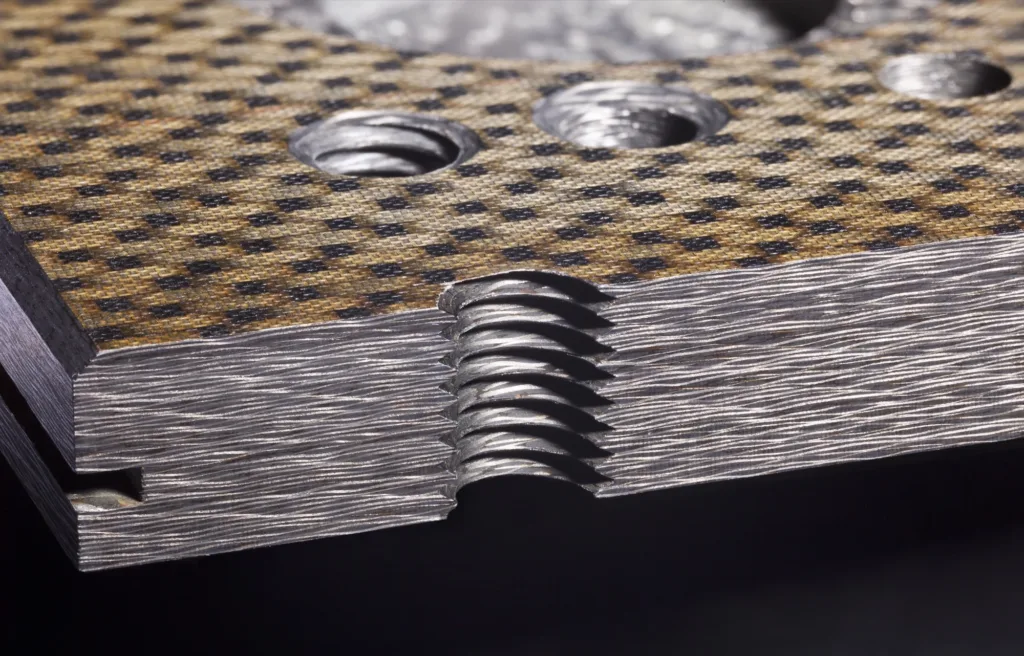

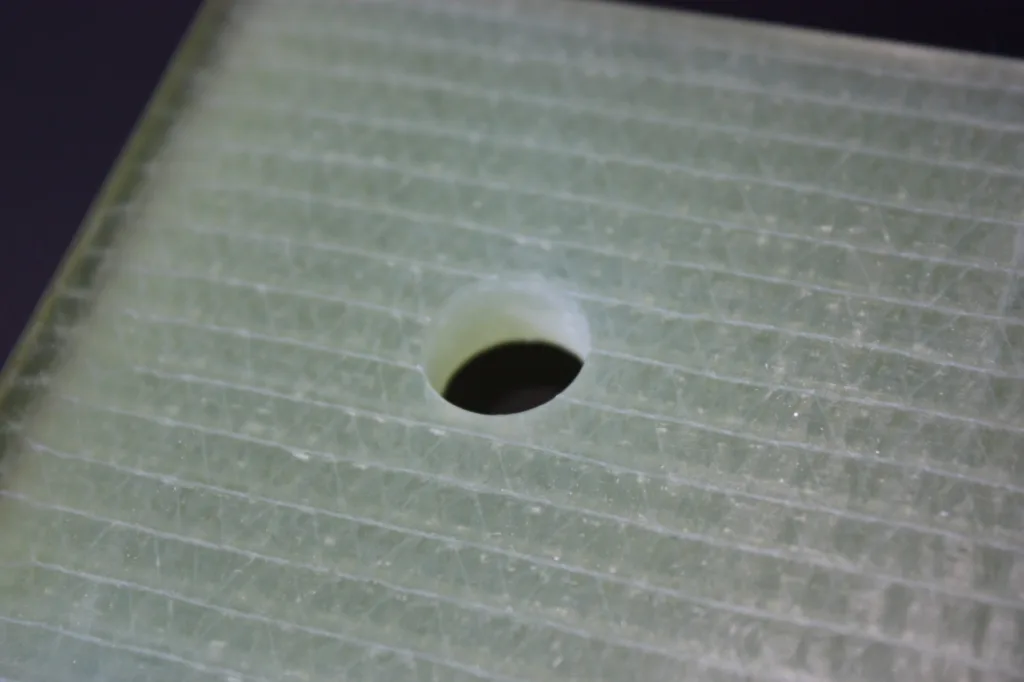

Hufschmied Drilling and milling tools have a chip geometry specially designed for the needs of “cold” machining and sharp, homogeneous cutting edges as outstanding properties. Due to this cutting edge geometry and its design, the plastic matrix materials in which the respective fibers are embedded are not heated. This keeps them harder and easier to cut through. The fibers are cut flush with the matrix and delamination, fiber protrusions or fraying are avoided. All tools are characterized by special hard metals that are optimized for the wear mechanisms of the fiber materials that occur with fiber-reinforced plastics.

Special chip breaker geometries for a reduced cutting force minimize the process forces that occur and also the process heat. This in turn avoids delamination, fraying or overhanging fibers on the components.

Hufschmied offers you a wide range of standard tools in various dimensions. Our team will also be happy to support you with individual solutions for machining composites. Optimized milling programs from our in-house CAD/CAM engineering department also ensure cost-efficient processing in every industry.