Hufschmied jetzt neu entdecken

Europas führender Hersteller für materialbezogene Werkzeuge

Vom Werkzeughersteller zum Prozess-Innovator

Vordenken statt

nachmachen.

Ralph Hufschmied über Hufschmied Technologie-Zentrum und Consulting

Unsere Helden

Working Heroes

T-REX Fräser – 194

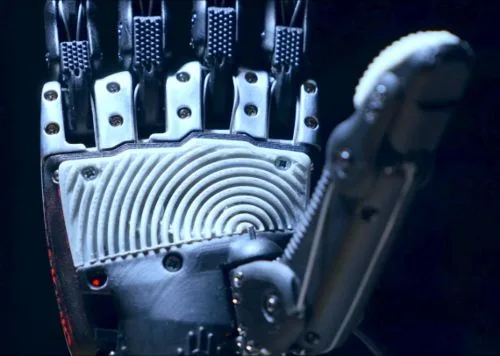

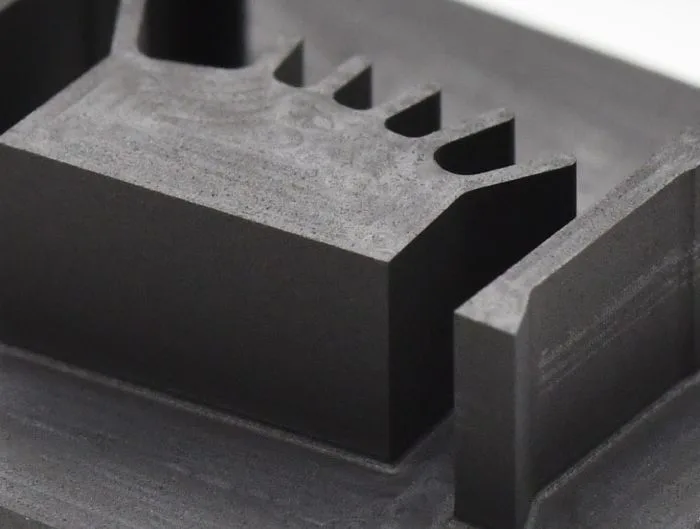

T-REX-Werkzeuge wurden für die Zerspanung von CFK-Strukturkomponenten und spezielle Anforderungen der Automobil- und Luftfahrtindustrie entwickelt. Mit seiner variablen Schneidengeometrie verbindet der T-REX die Vorteile der Fräsergeometrie mit der delaminationsfreien Trimmqualität eines Kompressionswerkzeugs. Daraus resultiert eine hohe Abriebfestigkeit für lange Werkzeugstandzeiten. Diese Neuentwicklung wird von HUFSCHMIED zum Patent angemeldet. Andere Zahngeometrien (schmal-, mittel- oder grobverzahnt) sind möglich.

Anwendung:

Fräsen von Randbesäumtaschen und Ausschnitten für CFK mit duroplastischen Harzen. Für thermoplastische Matrixsysteme ist eine weitere T-REX-Geometrie verfügbar.

Die Vorteile:

- Schruppen und Schlichten

- sehr hohe Werkzeugstandzeiten

- saubere Oberflächen

- verhindert Faserausrisse

- Delaminierungsfreie Bearbeitung

- hohe Dimensionsvielfalt

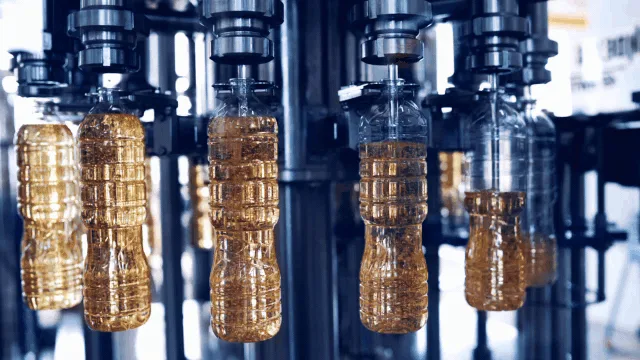

Shadowdrill – AD401

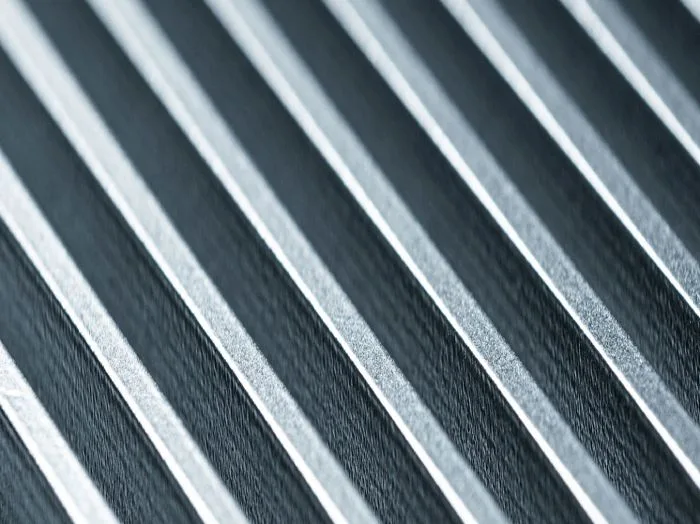

Schneller als sein Schatten. Ein spezieller Schliff sorgt für eine optimierte schnelle Spanabfuhr. In Kombination mit leistungsfähigen Werkstoffen und einer komplexer Schneidengeometrie kann der Shadowdrill auch extreme Anforderungen von besonders anspruchsvollen Bearbeitungsprozessen in Aluminium erfüllen.

Die Vorteile:

- Gratfreie Bearbeitung, sowohl bei Eintritt wie auch bei Austritt

- Ausgezeichnete Oberflächenqualität

- Hohe Vorschubgeschwindigkeit

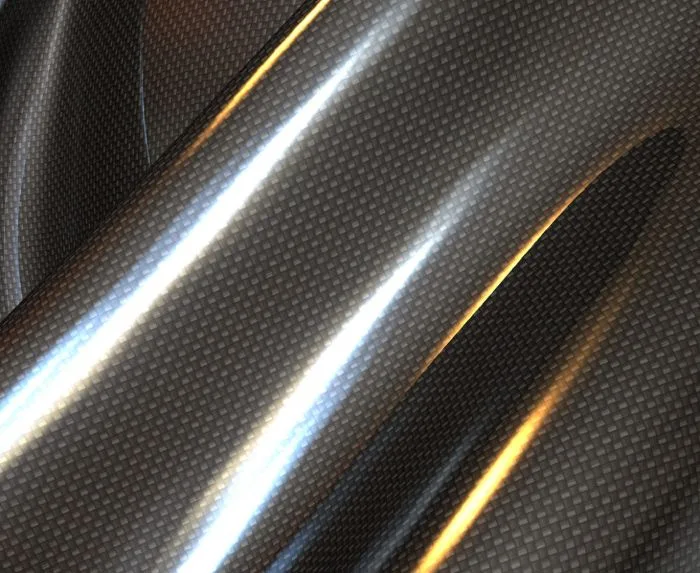

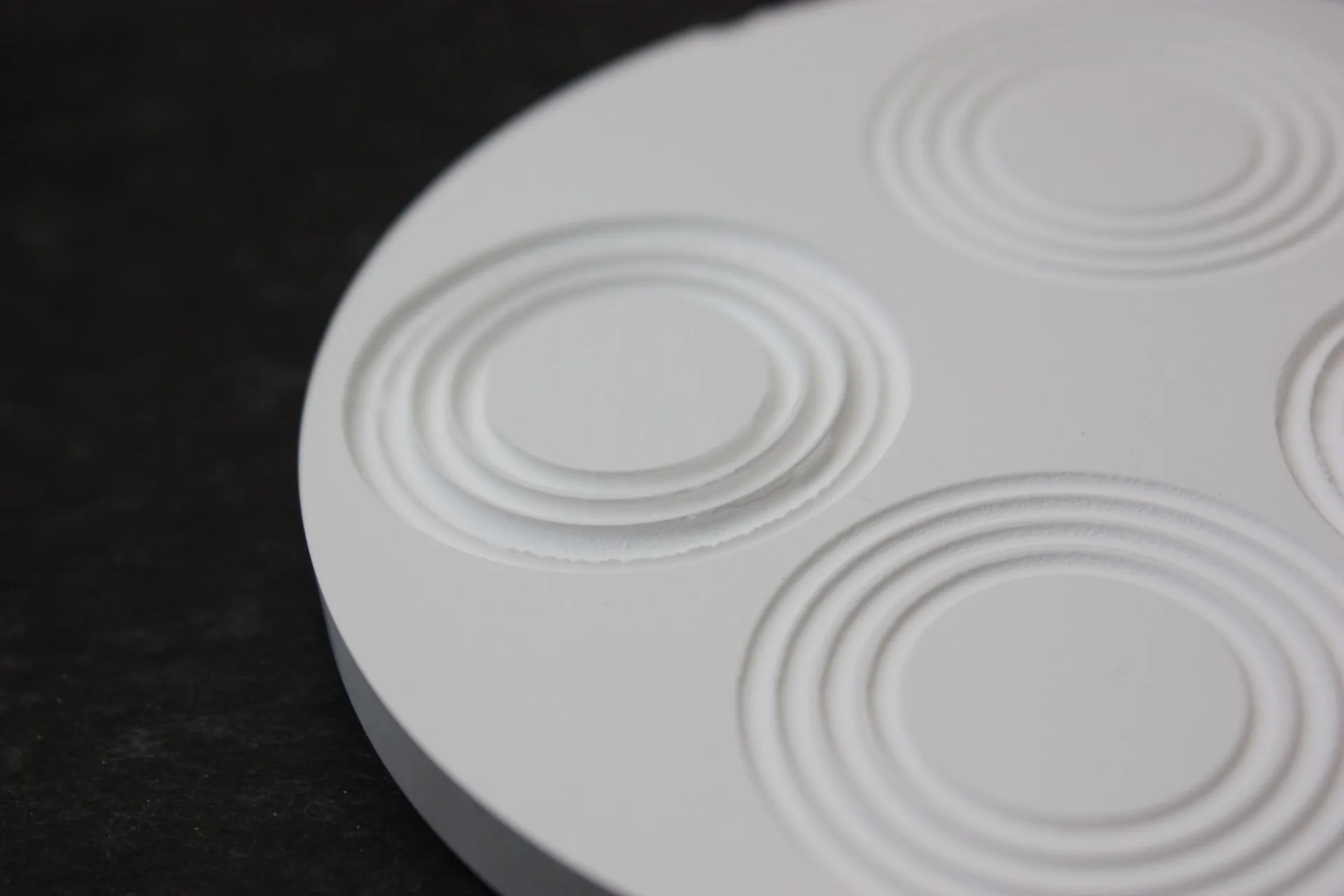

Wolverine HC403BD und Bonecrusher HC405BD

Effizienz und Schnelligkeit vereint – Dank einer einzigartigen Schneidengeometrie als Hochvolumenschruppfräser. Für eine optimale Bearbeitung von Aluminium erfordert es das perfekte Werkzeug. Entwickelt in Hufschmied’s eigenem Engineering-Center, ist der Wolverine HC403BD das Perfekte Werkzeug zum Abtragen von hohen Spanvolumina und für die Trochiodalbearbeitung.

Die Vorteile:

- Perfekter Spanfluss

- Massive Ausführung

- Kurze Schneiden

- Extreme Vorschübe darstellbar

Das sagen unsere Kunden

Stimmen aus der Industrie

Die Werkzeuge haben die besten Fans!